12v2835-60led/m 4000K

Send Inquiry

Our LED strips use high quality emitters, which can reproduce colors accurately and comfortably due to their relatively high CRI (color rendering index) of 97. This means that although they are slightly higher than their competitors, they will not give up green casting. This is not only suitable for home use, but also for photographers who want to use these strips to ignite the theme, because the skin color looks natural and vivid. Each strip is 5 meters long.

1. Product introduction 12v2835-60led/m 4000K

Color temperature – 2700K.3000K.4000K.5000K.6500K (100K error allowed). CRI: 97. Note: the color temperature may vary by 5% depending on the factory batch, although we try our best to keep consistency.

Package content - 1 x 5m LED light barw.

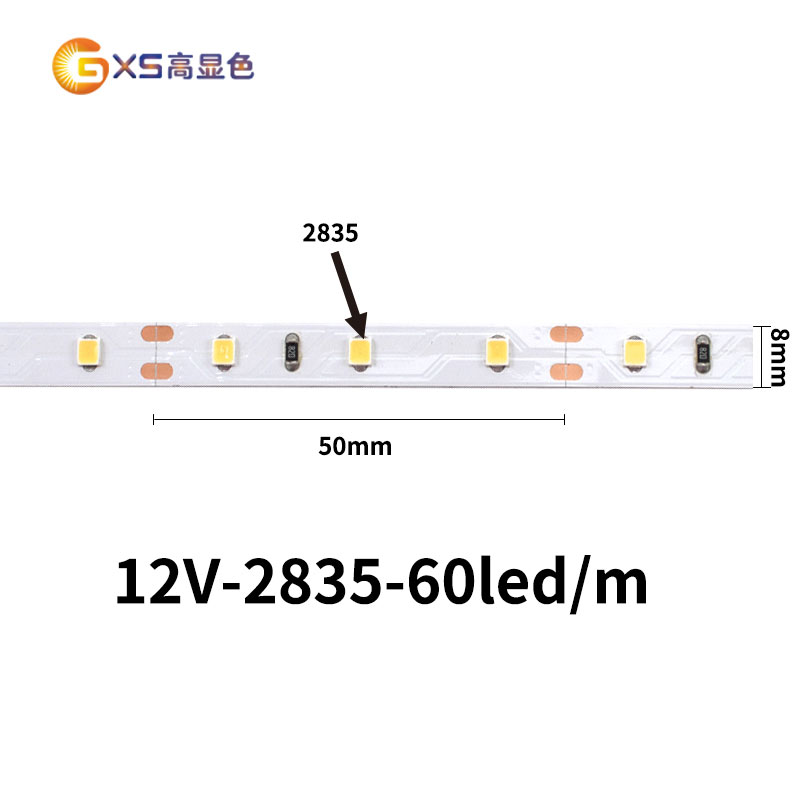

2. Product parameters 12v2835-60led/m 4000K

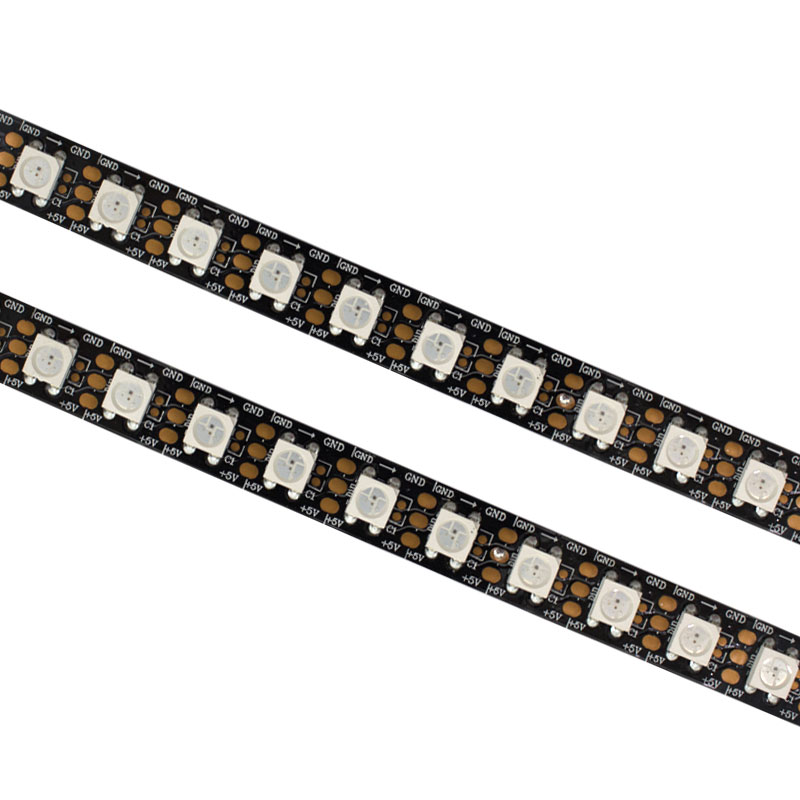

Light source: SMD 2835

CRI:>97

Color temperature (K):4000K

FPCB color: white

Protection grade: IP20 Not waterproof (Indoor use)

Led quantity: 60 LED / m, total 5m, 300 LED

Working voltage: 12V DC

Maximum working current: 5a

Power: 12W / m, 60W / roll

Beam angle: 120 degrees

Operating temperature: - 20 to 60 ℃

Dimensions: length 500 cm (5m) x width 0.8 cm x thickness 0.15 cm

Net weight: 100g

Service life: > 50000 hours

Warm tips: LED light bar does not contain power supply and controller.

Please note that

What is high display LED strip? Set the general color rendering number of sunlight and artificial standard light source close to sunlight as 100. For the same object, the higher the consistency between the color of the measured light source and that of the standard light source, the larger the RA, the better the color rendering performance, and vice versa.

The higher the display finger is, the more accurate the restoration color is. It has a good protective effect on the eyes. When accurate color contrast is needed, the color reducibility of high display finger is needed.

3. Detail shooting 12v2835-60led/m 4000K

4. Company production 12v2835-60led/m 4000K

1. Preparation before LED strip patch

Silica gel is used in the packaging process of SMD lamp beads, but silica gel is easy to absorb water. Once heated, the bracket will fall off or the gold wire will break due to thermal expansion and contraction, and there will be many dead lights after application. Before patching, we will place smd lamp beads in a constant temperature oven at 65° for 1-8 hours (the specific baking time depends on the lamp beads production time, the longer the production time, the longer the baking time, the longest No more than 8 hours)

2. LED strip printing solder paste.

After the solder paste is warmed up, stir it, and then put a small amount on the stencil of the printing machine. The amount should be 2/3 of the solder paste when the squeegee advances. After the first trial printing, check whether the solder paste at the LED pad position on the FPC is full and whether there is less or more tin.

3. LED strip patch test

Check the customer's product information and check whether the model, power and brightness of the SMD lamp bead are correct. Whether the resistance value and model match, and whether other special components are consistent with customer requirements. After all inspections are passed, the first sample will be mounted

4.led lamp with reflow soldering

It is necessary to check whether the reflow soldering temperature matches the solder paste used. If the temperature is too low, the solder paste will not melt, and cold soldering will occur; if the temperature is too high, the FPC is prone to blistering and yellowing, which will cause false soldering during reflow, and it may be produce tin beads.

5.Mid-term inspection of led lights

Conduct a comprehensive inspection of the semi-finished light strips, including whether the lamp bead resistance is skewed, whether the positive and negative electrodes of the lamp bead have patch errors, whether the brightness is uniform, and whether there are dirty tin beads on the surface. After the inspection is completed, the board connecting process can be entered.

6.led strip with connection board

Led strips are generally 50cm each, and the conventional shipping method is 5 meters. It can be shipped only after welding. During soldering, pay attention to whether the solder joints are full, and whether the connection between the light strip and the light strip is uneven and skewed.

7.Led strip with post-aging detection

The semi-finished 5m light strip is placed on the test stand, and the staff wears special glasses to inspect the light strip after lighting. Label the unlit lamp beads and have them repaired by maintenance personnel. During the inspection, pay attention to the multi-chip lights, and maybe only one chip does not light up. This is also a defective product and needs to be repaired. After the inspection, the remaining products without problems need to be energized and aged for 4-8 hours. During the period, the staff inspected from time to time.

8.led strip finished product processing

Comparing the customer's shipping requirements, processing double-sided tape, terminal wire, whether or not waterproof treatment and other processes, special products need to be beaten tested.

9.Led strip with finished packaging inspection

According to the customer's shipping requirements, check whether the label information and packaging materials of the prepared materials are consistent. The entire roll of the light strip needs to be energized and tested before being put into the bag. After power-on, check for dead lights. Power on the breakpoint 2 to 3 times to check whether the light strip is normal. When the lamp is energized, the front and back sides of the lamp belt are slapped on the static desktop to check whether there is a phenomenon of virtual welding. After all inspections are completed, the warehouse checks the labels and production documents for storage processing, and the light strips are shipped

4.FAQ

Q1. What is the Warranty for the led strips?

A1: For the led strips,we have 3 years warranty.If any quality problems on our side occur in this period ,we will take on the shipping cost and replacement.

Q2. Is there cheap shipping cost to import to our country?

A2: For small order,express will be best.And for bulk order,sea ship way is best but take much time.

For urgent orders,we suggest via air to airport plus our ship partner send to your door.

Q3. What's your leadtime?

A3. The sample order leadtime will be 3-5days .

Small batch order 10-15 days

Negotiable delivery time for large orders

Q4. Can I have a sample order for led strip?

A4: Yes, we welcome sample order to test and check quality.

Q5. What is your produce ability?

A5. We are a professinal manufacture led strip in Shenzhen and we can supply 400,000 meters per month.

Q6.Do you accept customized products?

A6.Yes, we accept customized products. We can produce all kinds of led strip products according to your requirements

English

English